What Is the Role of Cobalt in Cemented Carbide Processes?

Cemented carbide is renowned for its exceptional hardness, wear resistance, and elastic modulus, particularly at elevated temperatures. It holds a critical position in modern tool materials, wear-resistant components, and high-temperature/corrosion-resistant applications. Cobalt-bonded tungsten carbide (WC-Co) is widely used as a cutting tool material in industry. Cobalt’s superior wettability and bonding capability with hard phases like WC and TiC, along with its high solubility for these carbides, endows cobalt-bonded cemented carbide with outstanding strength, hardness, and wear resistance.

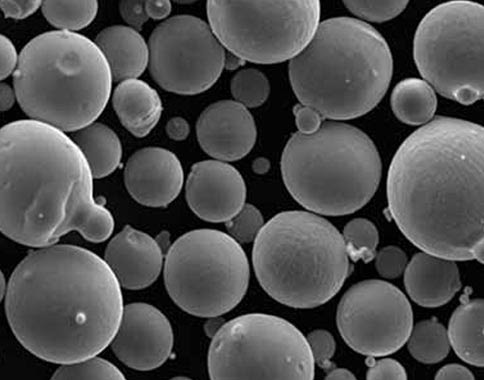

Cobalt serves as the binder metal in cemented carbide, where its room-temperature plastic deformation capability provides the alloy with impact-resistant toughness. Cemented carbide is formed through liquid-phase sintering, and the binder metal's ability to wet the hard phases (e.g., tungsten carbide, TiC) plays a critical role in producing high-quality sintered products. While cobalt and nickel are both considered versatile binders for cemented carbide, over 90% of cemented carbide grades rely on cobalt as the primary binder. Cobalt’s unique properties—such as its exceptional wettability, solubility control during sintering, and balanced compatibility with carbide phases—make it indispensable in achieving the alloy’s optimal mechanical strength, wear resistance, and thermal stability. This dominance underscores cobalt’s irreplaceable influence on cemented carbide manufacturing and performance.

Cemented carbide is composed of hard carbide phases and a ductile binder metal. The carbide phases (e.g., tungsten carbide, TiC) provide the alloy with load-bearing capacity and wear resistance, while the binder metal (typically cobalt) imparts impact-resistant toughness through its ability to undergo plastic deformation at room temperature. Cemented carbide is manufactured via liquid-phase sintering, where the wettability of the binder metal to the carbide phases is critical for achieving a dense, homogeneous microstructure and high-performance sintered products.

Cobalt’s high-performance alloy steels and premium alloys are extensively used in the aerospace industry, such as in aircraft engine components and structural airframe parts. The tungsten-cobalt (WC-Co) cemented carbide series is critical for applications requiring extreme surface hardness, including cutting tool inserts for machining high-strength materials, wear-resistant mining equipment, and durable surgical instruments. Additionally, certain high-strength permanent magnets, such as samarium-cobalt (SmCo) alloys, leverage cobalt’s exceptional magnetic properties for advanced industrial and technological applications.

Tianyi High-Tech steadfastly upholds its philosophy of "crafting superior products and services," prioritizing the use of premium raw materials. Cobalt, as a critical component, serves as a key benchmark for evaluating product quality. Our commitment to excellence ensures that every cemented carbide product—from roll rings to cutting tools—delivers unmatched durability and precision, meeting the stringent demands of industries ranging from metalworking to aerospace.

Related product categories

- custom size roll rings for steel mills

- top suppliers of tungsten carbide roll rings for high-temperature applications

- China carbide roller rings

- China benefits of using cemented carbide roll rings

- carbide roll ring maintenance for dable carbide roll rings

- how to select carbide roll rings for high-temperature applications

- rolling mill roller rings Italy

- carbide roll ring maintenance United States

- cemented carbide rolls for grooving

- china cnc router end mill bits

- router milling bits

- china milling router bit

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de