Cemented Carbide Composite Rolls

Product Information

-

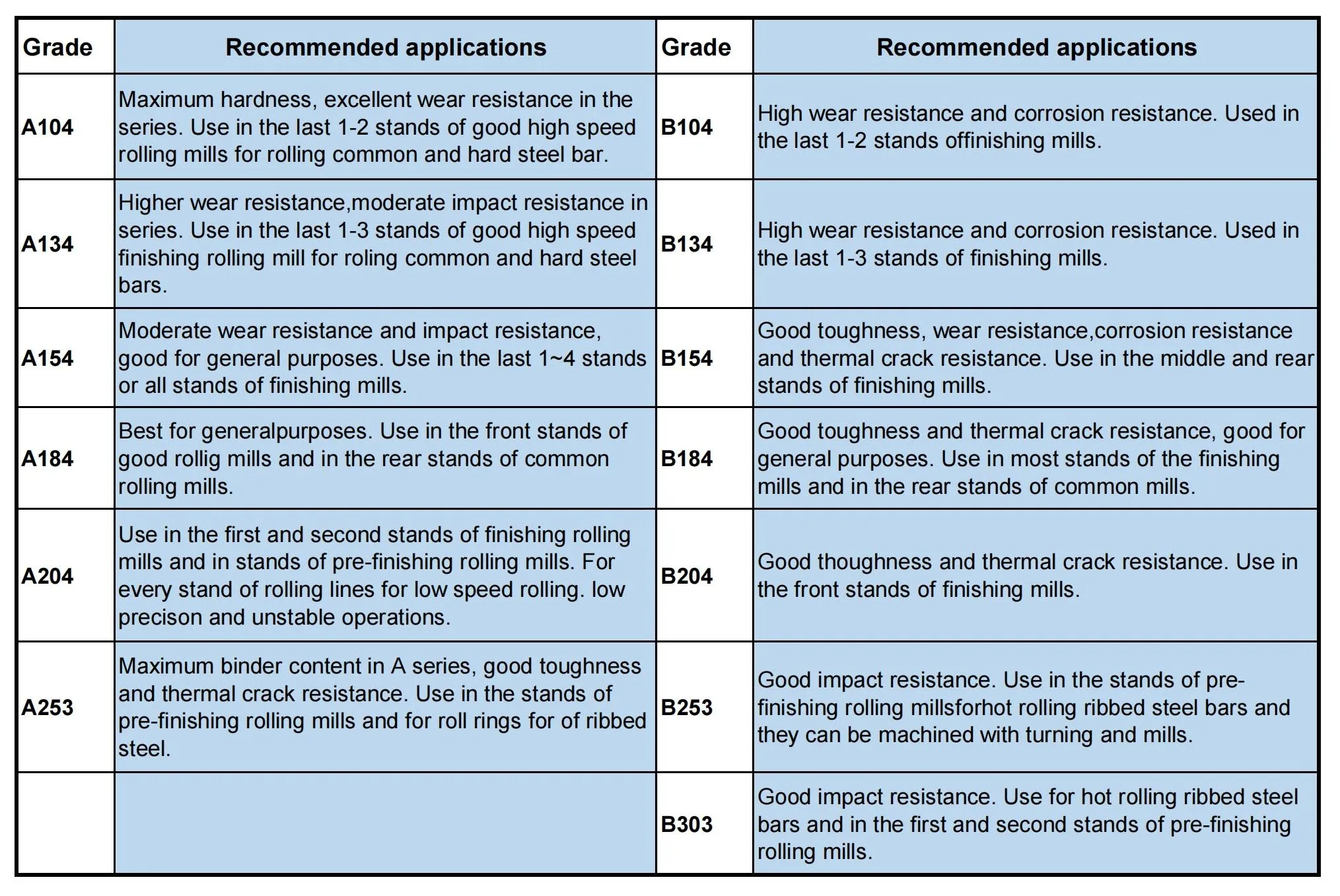

Specialized Materials: We utilize special cemented carbide grades designed for hot rolling rods and ribbed steel bars.

-

Secure Hydraulic Locking System: Hydraulic nuts, supplied with oil at 100-200 MPa, generate an axial pre-tightening force of 500-1500kN. This fastens the cemented carbide roll rings securely to the mother shafts. The system is practical, reliable, and ensures enhanced composite roll ring performance through proper prestress protection.

-

Sizing Mill Roll Rings: We offer various cemented carbide roll rings for sizing mills, with diameters of φ300-400mm and thicknesses ranging from 30mm to 159mm.

-

Hot Rolling Solutions: We provide various composite cemented carbide roll rings specifically for hot rolling ribbed steel bars and rods.

-

Custom Manufacturing Services: Our capabilities include composite roll design, groove machining, and thread processing.

-

Compatible Tooling: We supply various compatible tools for machining composite cemented carbide roll rings.

Description

Technical Parameter

Cemented carbide roll rings (also known as Tungsten Carbide Roll Rings) provide excellent thermal conductivity and outperform first-generation cast iron and high-speed steel rolls in heat resistance, wear resistance, and strength, with minimal hardness reduction at high temperatures. Developed alongside high-speed wire rod mills, they are now extensively applied in the finishing stands for manufacturing high-speed wire, rebar, and deformed steel bars.

1) The rolling quantity of composite cemented carbide rolls

|

Specification (mm)

|

The rolling quantity of a single groove (ton) |

||

|

Stands of finished products K1 |

The front stands of finished products K2 |

Slitter K3、K4 |

|

|

φ10 |

>600 |

>1500 |

>3000 |

|

φ12 |

>800 |

>2000 |

>4000 |

|

φ14 |

>1400 |

>3000 |

>6000 |

|

φ16 |

>1600 |

>3500 |

>7000 |

|

φ18 |

>1800 |

>4000 |

>8000 |

|

φ20 |

>2000 |

>5000 |

|

|

φ22 |

>2200 |

>6000 |

|

|

φ25 |

>2500 |

>8000 |

|

2) Cemented carbide composite rolls specifications

|

Outer diameter range(mm) |

Width range(mm) |

Rolling size range(mm) |

|

285-480 |

50-140 |

5-28 |

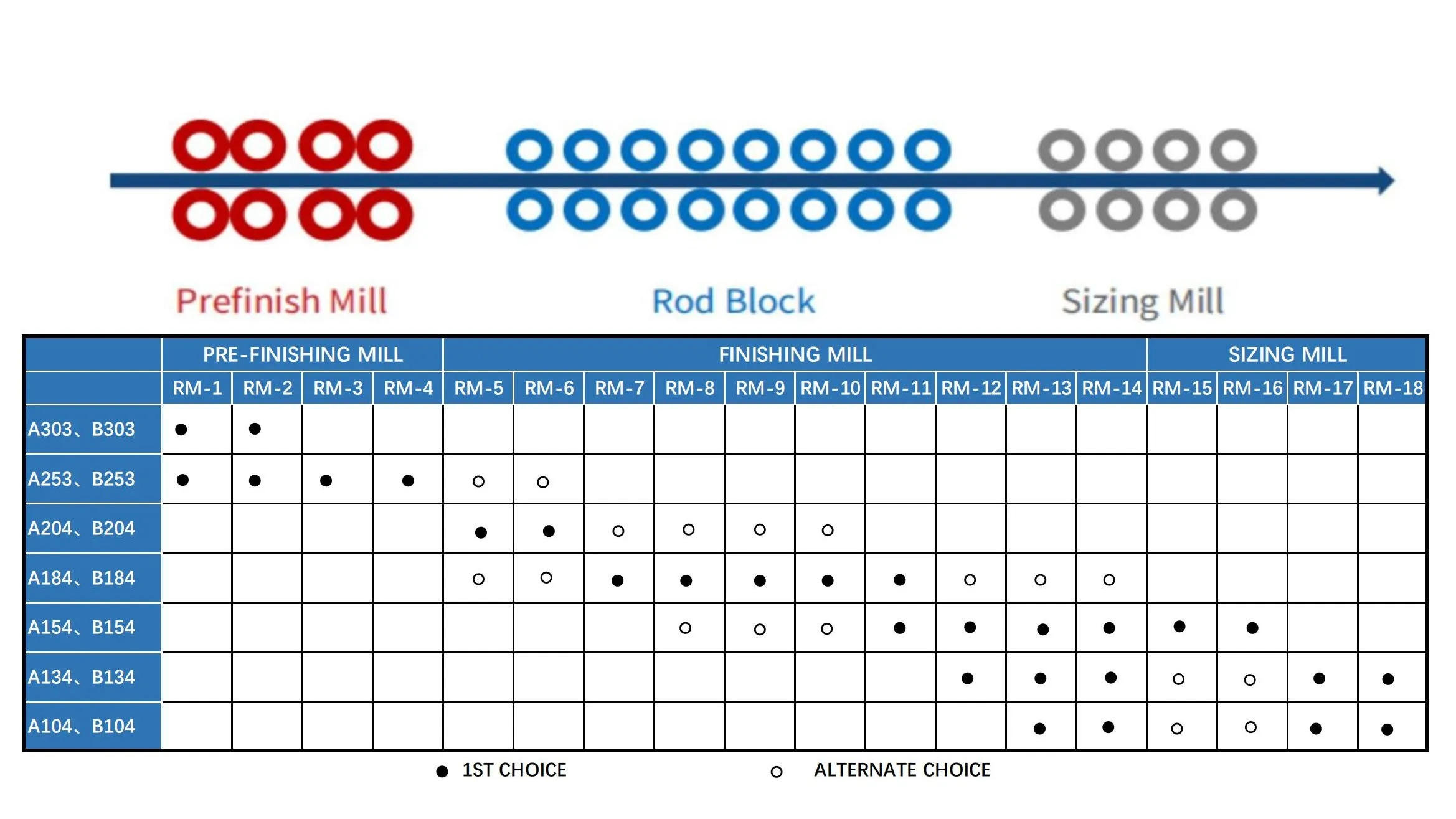

3) Rolling process for hot rolling rods and rebar

|

Name |

Single rolling |

2clit rolling |

3clit rolling |

Recommend materials |

|

K1 Group |

|

|

|

Cemented carbide |

|

K2 Group |

|

|

|

Cemented carbide |

|

K4 Group |

|

|

|

Cemented carbide |

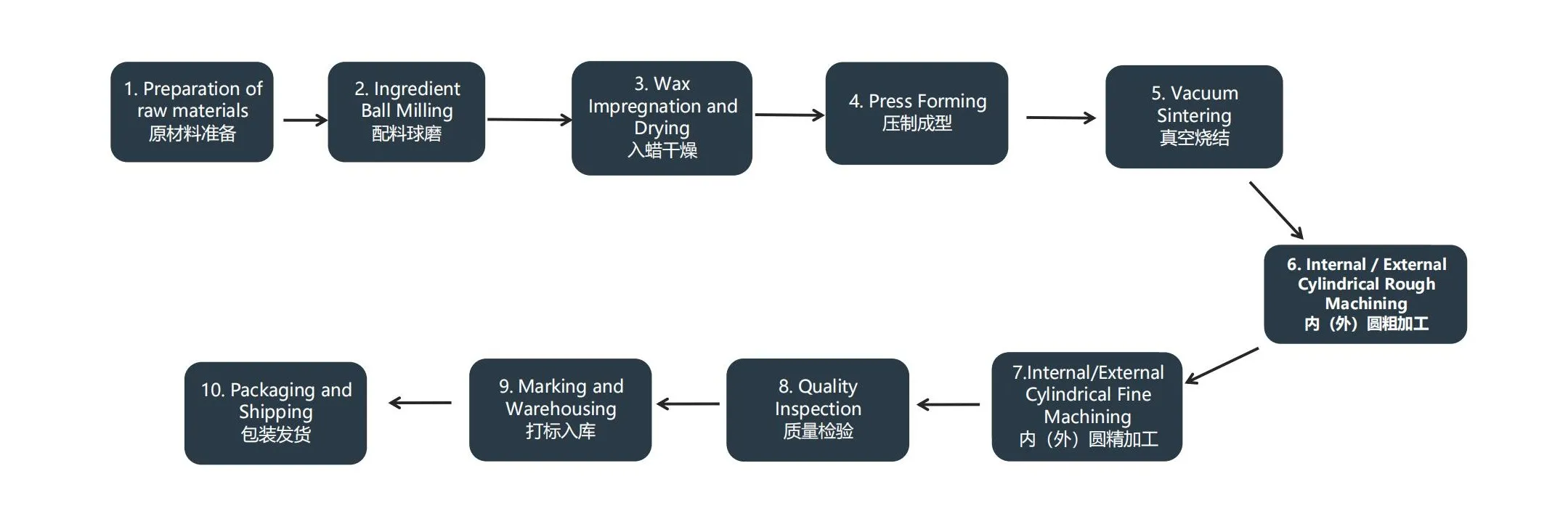

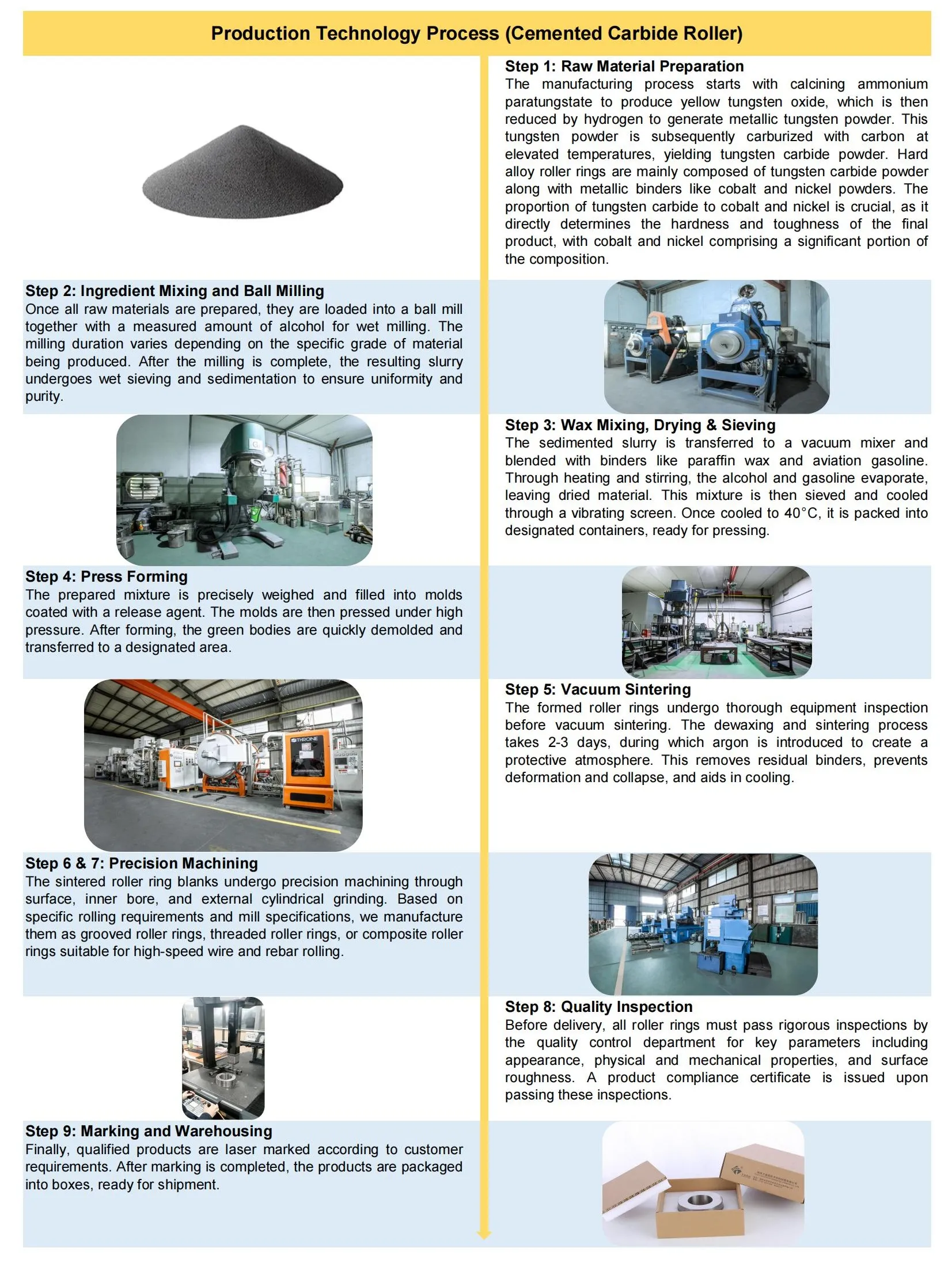

Production Technology Process

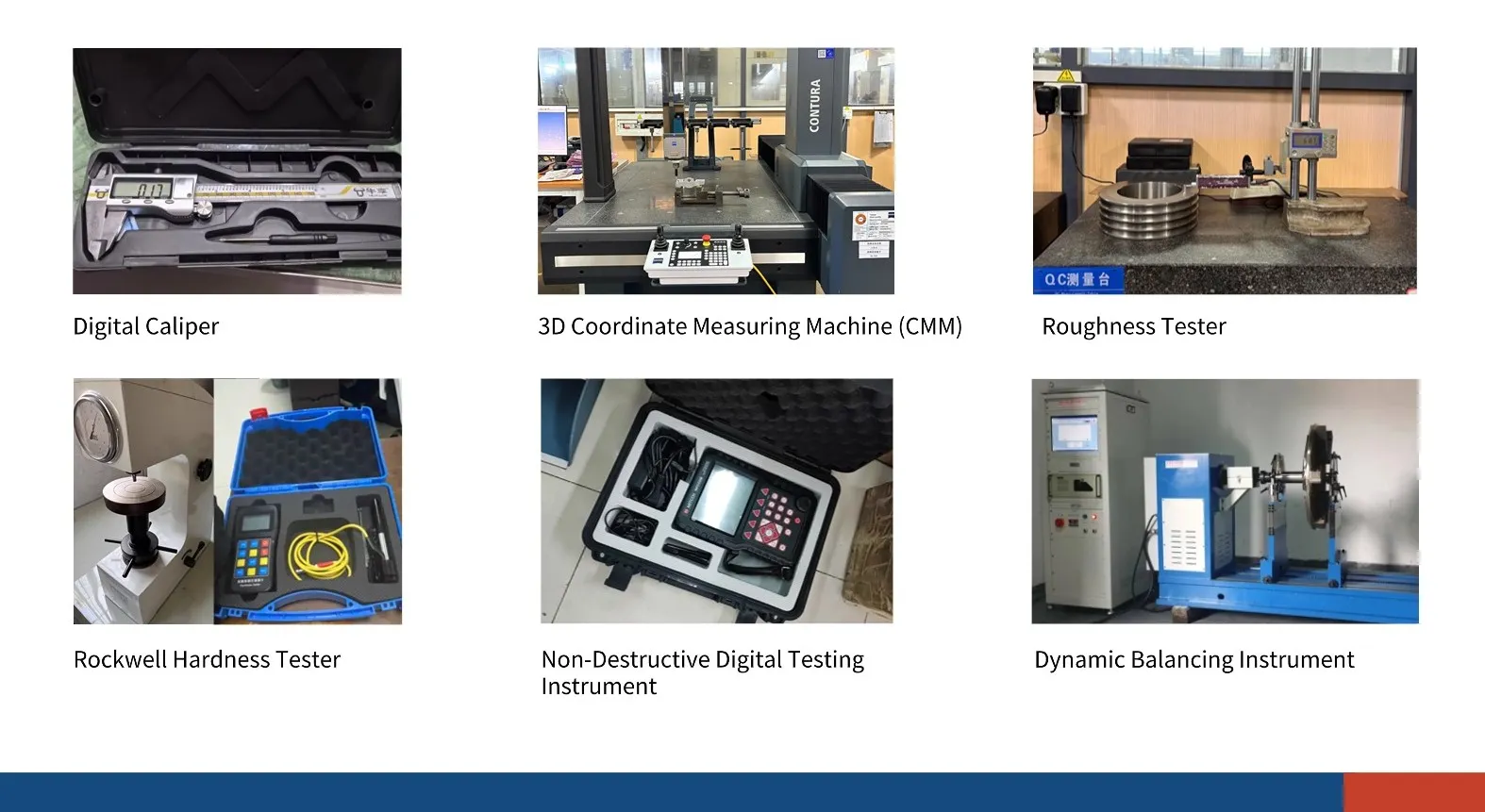

Quality Inspection Equipment

INQUIRY

Related product categories

- cemented carbide rolls Turkey for steel industry

- large diameter carbide roll rings for cold rolling

- ISO-certified carbide roll rings for roll rings

- OEM carbide roll rings for bar mills

- carbide rolls for cold rolling mills

- China carbide roll rings for steel mills

- cemented carbide blank for wood cutting

- wholesale carbide roll rings United States

- carbide rolls Malaysia

- china cnc roughing end mill supplier

- hobby cnc end mill

- china cnc plexiglass end mill

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de