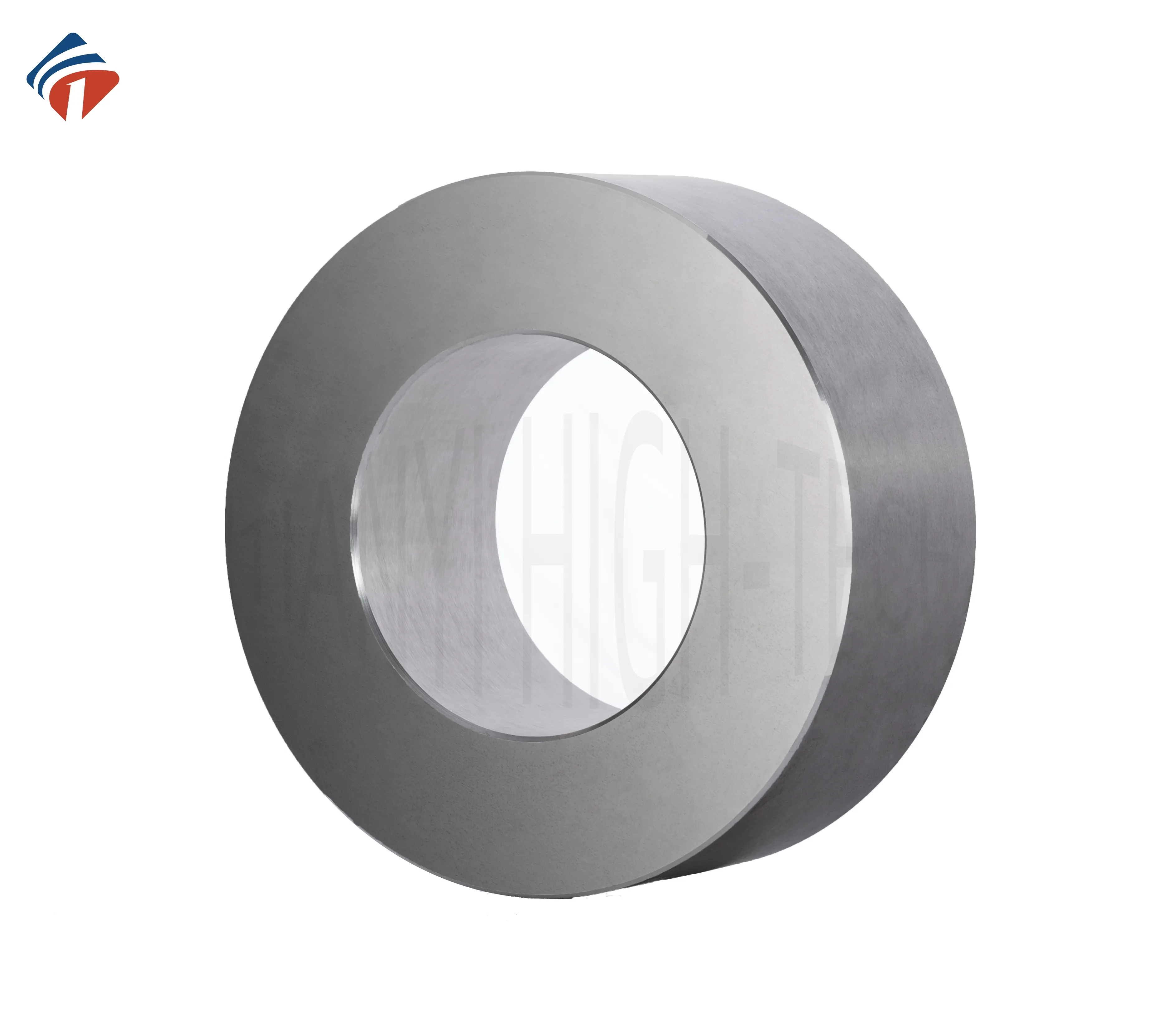

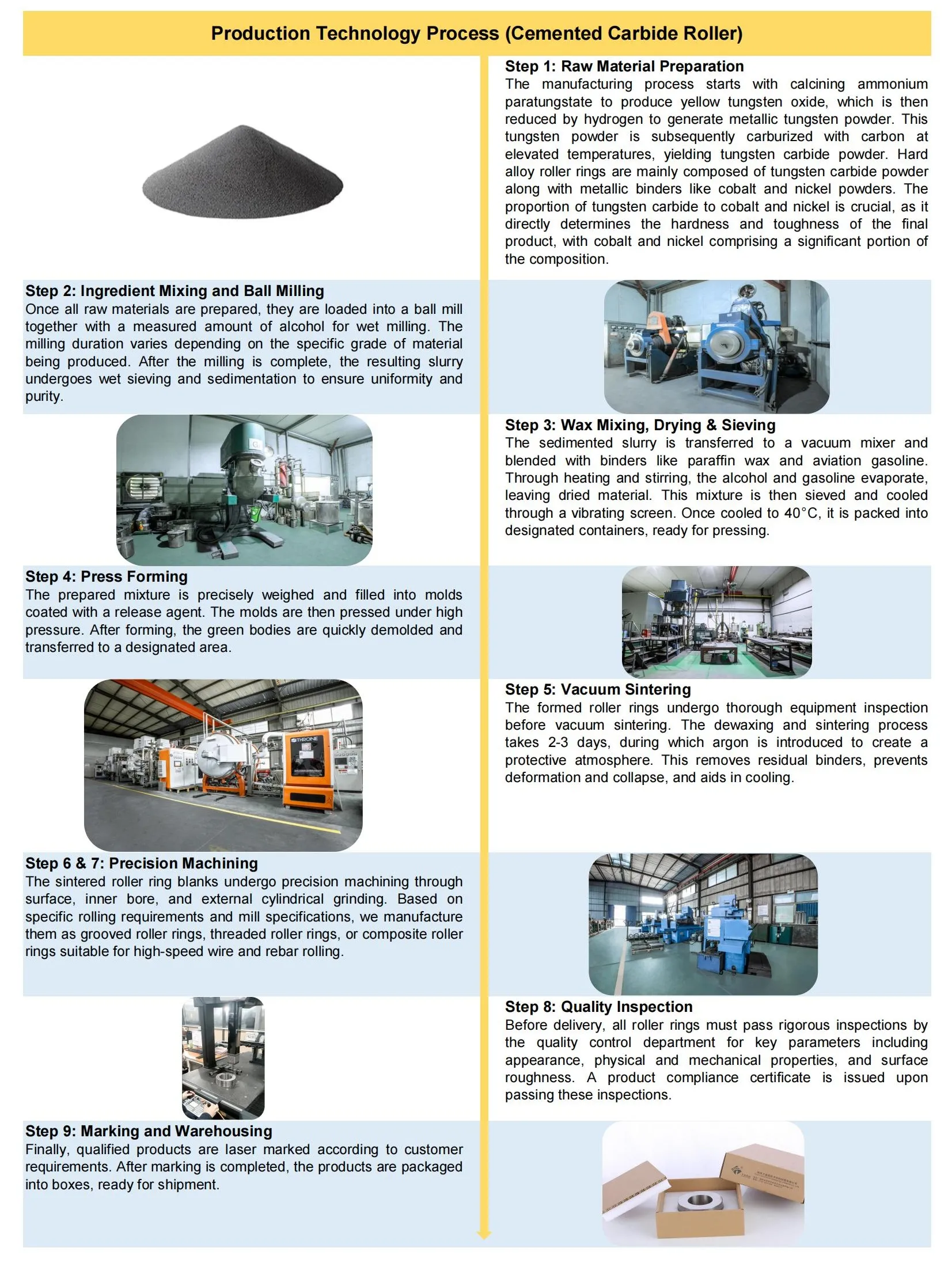

High Performance Tungsten Carbide Thread Roll Ring With Ribs

Product Information

- Material: WC, Metallic binder (Cobalt, Nickel, etc.)

- Roller Style: Light roller / Grooving roller/ Threaded roller.

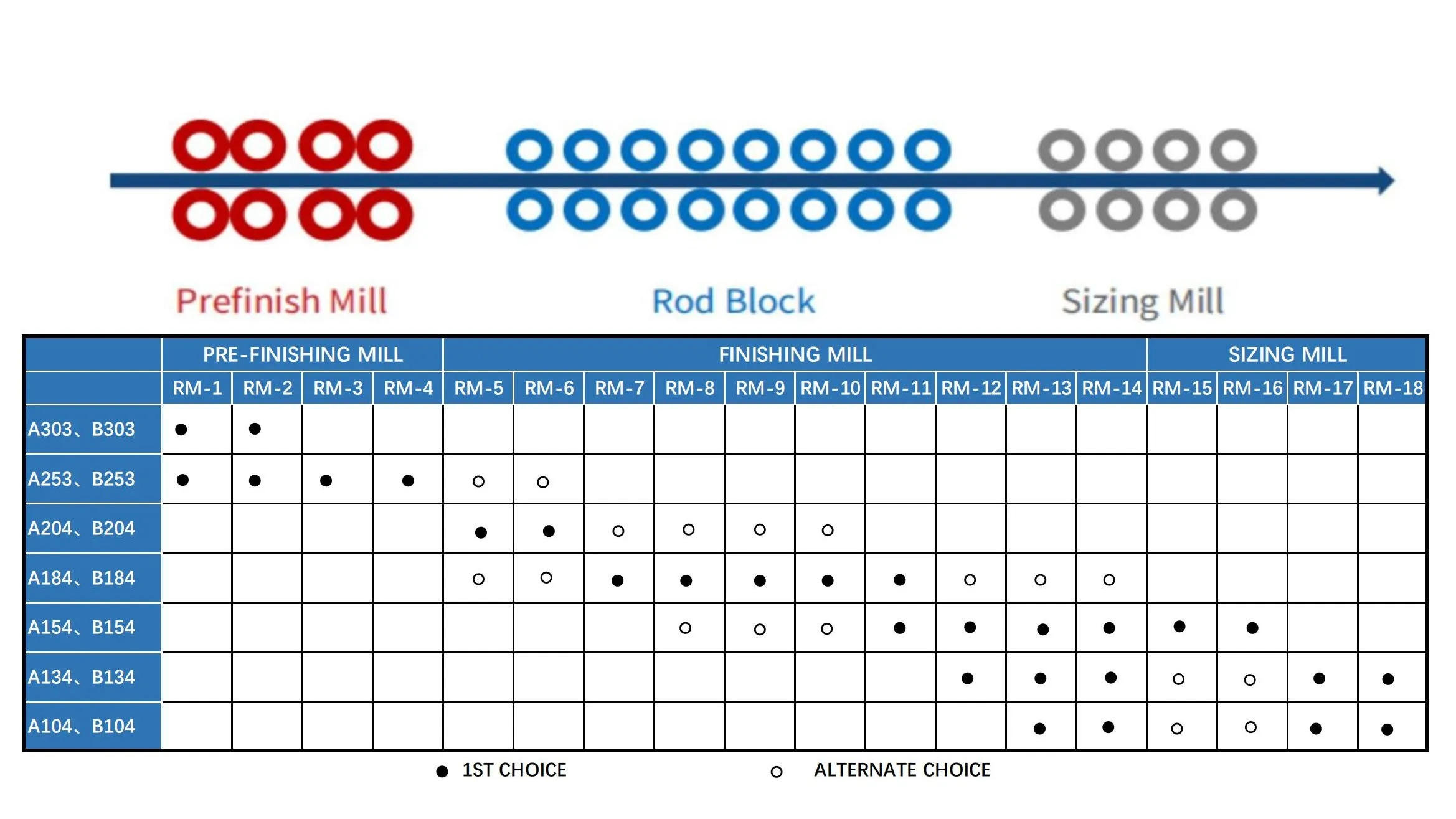

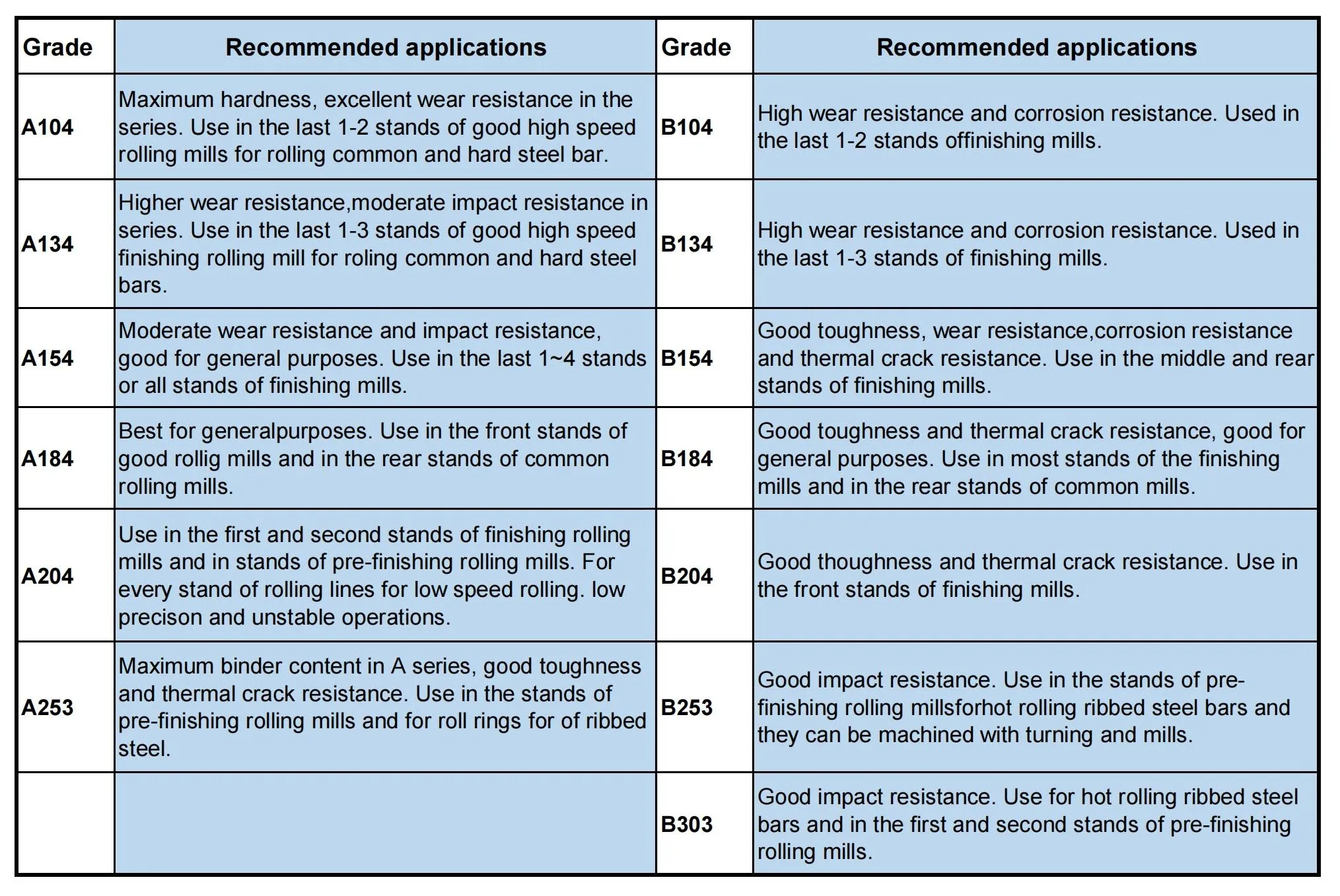

- Application: Pre-finish mill & Finishing mill & Sizing mill in the rolling mill.

- Types of Rolling: Hot Rolling(High-Temperature), Cold Rolling (Room temperature).

- Surface: Polishing.

- Advantage: exceptional hardness, high wear resistance, high resistance, and durability.

- Certification: ISO Certificate.

- Other Services: OEM/ODM.

Description

Technical Parameter

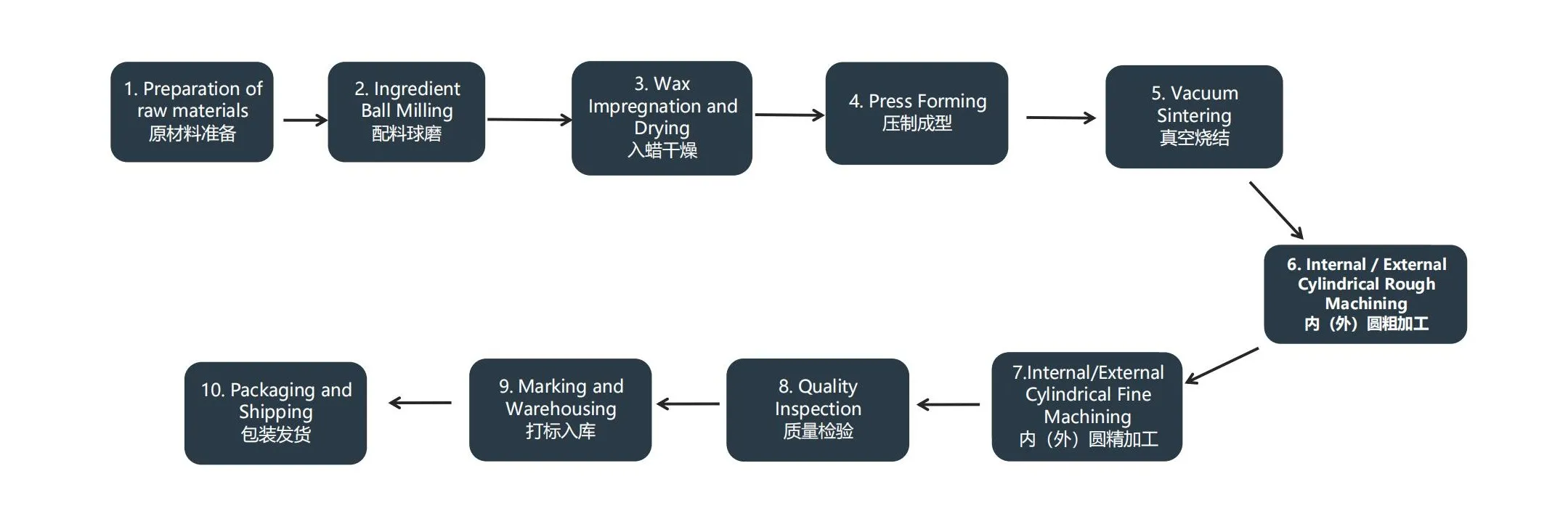

Cemented carbide roll rings (also known as Tungsten Carbide Roll Rings) offer excellent thermal conductivity and outperform first-generation cast iron and high-speed steel rolls in terms of heat resistance, wear resistance, and strength, with minimal hardness reduction at high temperatures. Developed alongside high-speed wire rod mills, they are now extensively applied in the finishing stands for manufacturing high-speed wire, rebar, and deformed steel bars.

| Roughness of carbide rolls | |

| Inner hole roughness: | 0.4μm |

| Periphery roughness: | 0.4μm |

| End face roughness: | 0.4μm |

| The specification of the cemented carbide roller | ||

| Range of O.D. | Range of I.D. | Range of Height |

| 145-330 | 87-260 | 45-130 |

| The allowable deviation of carbide roll rings | |||

| Radial runout of groove: | ≤0.013mm | Radial runout of excircle: | ≤0.013mm |

| End face runout: | ≤0.02mm | End face planeness: | ≤0.01mm |

| End face parallelism: ≤0.01mm | ≤0.01mm | Inner hole cylindericity: | ≤0.01m |

| The tolerances allowable for the outer diameter, inner diameter, and height of roll rings. | |||||

| Precision Index | 1 | 2 | 3 | 4 | Customization Service We can customize your size & materials according to the drawings provided by customers. |

| O.D. (±) | 0.02 | 0.05 | 0.1 | 0.15 | |

| I.D. (±) | IT 5 | IT6 | IT7 | IT8 | |

| Height(-) | 0.03 | 0.1 | 0.2 | 0.5 | |

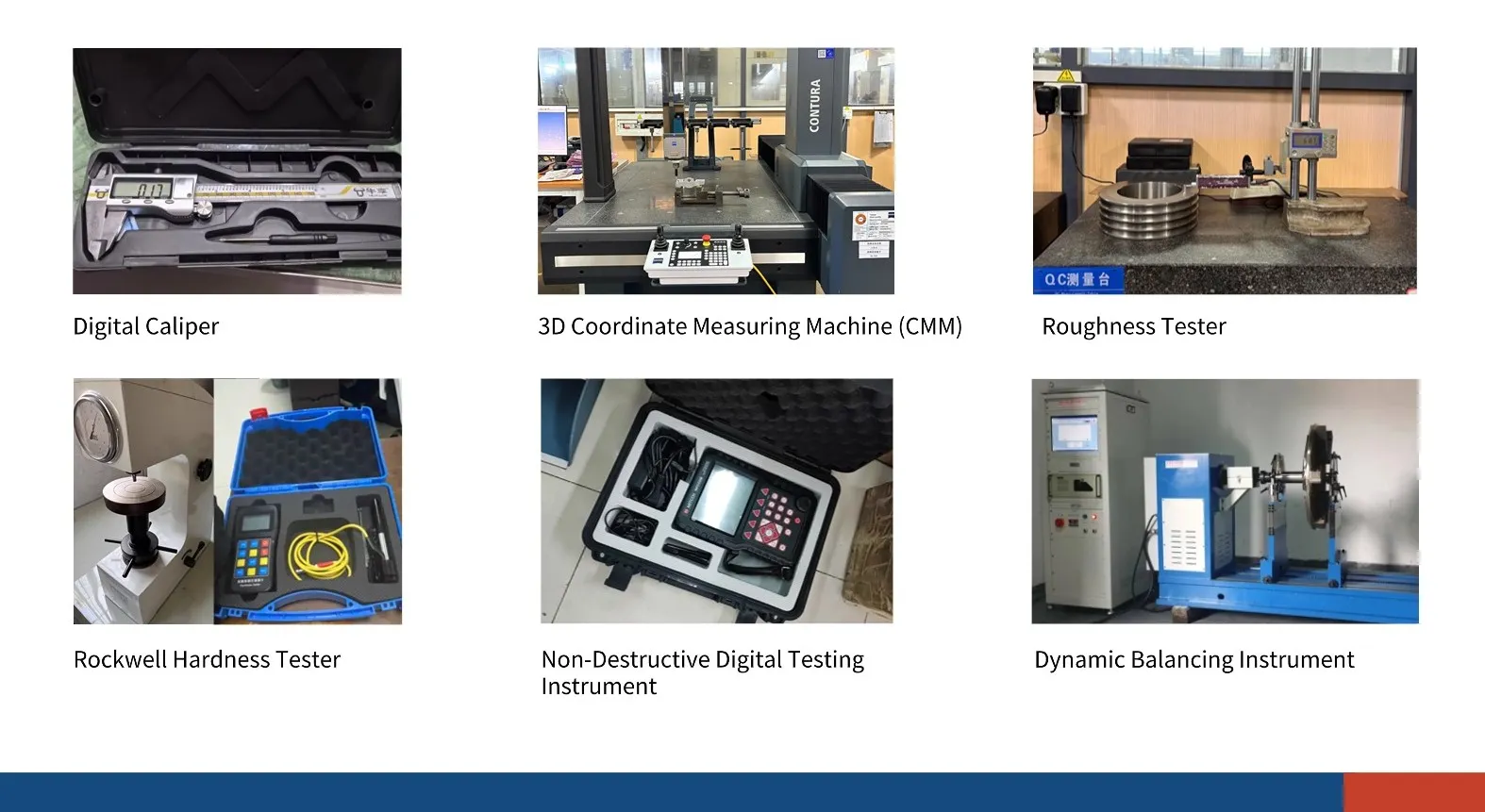

Quality Inspection Equipment

INQUIRY

Related product categories

- carbide rolls for mance roller rings

- rolls for OEMs

- carbide roll rings with tight tolerances for bar mills

- long-lasting carbide roll rings for special steel manufacturing

- roller rings compatible with SMS Group for steel industry

- thermally stable carbide rolls for special steel manufacturing

- roll rings Saudi Arabia

- corrosion-resistant carbide rolls Iraq

- cemented carbide cutting tool for deburring

- china cemented solid tungsten carbide rod

- 1 4 end mill bit

- cnc roughing end mill supplier

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de