Description

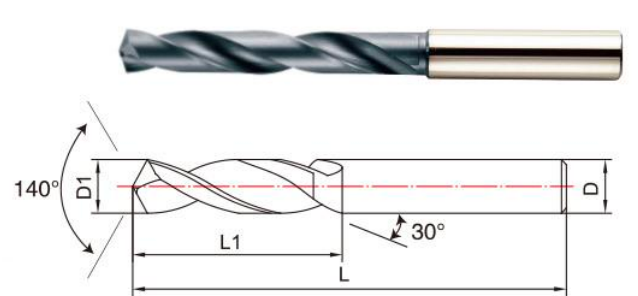

Solid carbide twist drill, 5xD

★Manufacturing characteristics

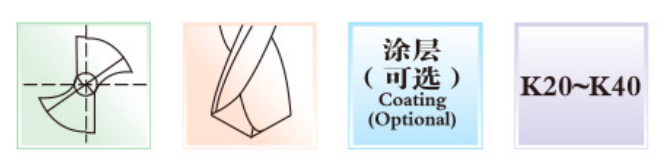

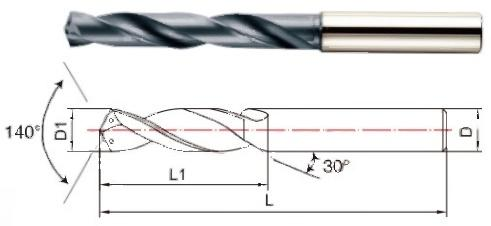

1. Dimensions are manufactured according to DIN6537 standard 2. Chisel edge correction IRK standard

3. Main edge angle 140°

4. Special chip groove design for easy chip removal

5. Blade diameter tolerance m7

6. Shank diameter type refers to DIN6535HA h6

★Usage Features

Used for processing common materials such as structural steel, alloy steel, stainless steel, etc.; has strong centering ability, can obtain stable dimensional accuracy and good surface quality; suitable for occasions where the processing system has excellent rigidity.

|

Size series |

Size Features |

Size series |

Size Features |

||||

|

D1 |

L1 |

D |

L |

D1 |

L1 |

D |

L |

|

3 |

16 |

3 |

50 |

5.5 |

25 |

5.5 |

60 |

|

3.1 |

18 |

3.1 |

50 |

5.6 |

25 |

5.6 |

60 |

|

3.2 |

18 |

3.2 |

50 |

5.7 |

25 |

5.7 |

60 |

|

3.3 |

18 |

3.3 |

50 |

5.8 |

25 |

5.8 |

60 |

|

3.4 |

20 |

3.4 |

50 |

5.9 |

25 |

5.9 |

60 |

|

3.5 |

20 |

3.5 |

50 |

6.0 |

30 |

6.0 |

70 |

|

3.6 |

20 |

3.6 |

50 |

6.1 |

30 |

6.1 |

70 |

|

3.7 |

20 |

3.7 |

50 |

6.2 |

30 |

6.2 |

70 |

|

3.8 |

20 |

3.8 |

50 |

6.3 |

30 |

6.3 |

70 |

|

3.9 |

20 |

3.9 |

55 |

6.4 |

30 |

6.4 |

70 |

|

4.0 |

20 |

4.0 |

55 |

6.5 |

30 |

6.5 |

70 |

|

4.1 |

20 |

4.1 |

55 |

6.6 |

30 |

6.6 |

70 |

|

4.2 |

20 |

4.2 |

55 |

6.7 |

30 |

6.7 |

70 |

|

4.3 |

20 |

4.3 |

55 |

6.8 |

30 |

6.8 |

70 |

|

4.4 |

20 |

4.4 |

55 |

6.9 |

30 |

6.9 |

70 |

|

4.5 |

20 |

4.5 |

55 |

7.0 |

35 |

7.0 |

80 |

|

4.6 |

20 |

4.6 |

55 |

7.1 |

35 |

7.1 |

80 |

|

4.7 |

20 |

4.7 |

55 |

7.2 |

35 |

7.2 |

80 |

|

4.8 |

20 |

4.8 |

55 |

7.3 |

35 |

7.3 |

80 |

|

4.9 |

20 |

4.9 |

55 |

7.4 |

35 |

7.4 |

80 |

|

5.0 |

25 |

5.0 |

60 |

7.5 |

35 |

7.5 |

80 |

|

5.1 |

25 |

5.1 |

60 |

7.6 |

35 |

7.6 |

80 |

|

5.2 |

25 |

5.2 |

60 |

7.7 |

35 |

7.7 |

80 |

|

5.3 |

25 |

5.3 |

60 |

7.8 |

35 |

7.8 |

80 |

|

5.4 |

25 |

5.4 |

60 |

7.9 |

35 |

7.9 |

80 |

|

8.0 |

40 |

8.0 |

90 |

10.5 |

43 |

10.5 |

100 |

|

8.1 |

40 |

8.1 |

90 |

10.6 |

43 |

10.6 |

100 |

|

8.2 |

40 |

8.2 |

90 |

10.7 |

43 |

10.7 |

100 |

|

8.3 |

40 |

8.3 |

90 |

10.8 |

43 |

10.8 |

100 |

|

8.4 |

40 |

8.4 |

90 |

10.9 |

43 |

10.9 |

100 |

|

8.5 |

40 |

8.5 |

90 |

11 |

45 |

11 |

100 |

|

8.6 |

40 |

8.6 |

90 |

11.1 |

45 |

11.1 |

100 |

|

8.7 |

40 |

8.7 |

90 |

11.2 |

45 |

11.2 |

100 |

|

8.8 |

40 |

8.8 |

90 |

11.3 |

45 |

11.3 |

100 |

|

8.9 |

40 |

8.9 |

90 |

11.4 |

45 |

11.4 |

100 |

|

9.0 |

40 |

9.0 |

90 |

11.5 |

45 |

11.5 |

100 |

|

9.1 |

40 |

9.1 |

100 |

11.6 |

45 |

11.6 |

100 |

|

9.2 |

40 |

9.2 |

100 |

11.7 |

45 |

11.7 |

100 |

|

9.3 |

40 |

9.3 |

100 |

11.8 |

45 |

11.8 |

100 |

|

9.4 |

40 |

9.4 |

100 |

11.9 |

45 |

11.9 |

100 |

|

9.5 |

40 |

9.5 |

100 |

12.0 |

50 |

12.0 |

100 |

|

9.6 |

40 |

9.6 |

100 |

12.1 |

50 |

12.1 |

100 |

|

9.7 |

40 |

9.7 |

100 |

12.2 |

50 |

12.2 |

100 |

|

9.8 |

40 |

9.8 |

100 |

12.3 |

50 |

12.3 |

100 |

|

9.9 |

40 |

9.9 |

100 |

12.4 |

50 |

12.4 |

100 |

|

10 |

40 |

10 |

100 |

12.5 |

50 |

12.5 |

100 |

|

10.1 |

43 |

10.1 |

100 |

12.6 |

50 |

12.6 |

100 |

|

10.2 |

43 |

10.2 |

100 |

12.7 |

50 |

12.7 |

100 |

|

10.3 |

43 |

10.3 |

100 |

12.8 |

50 |

12.8 |

100 |

|

10.4 |

43 |

10.4 |

100 |

12.9 |

50 |

12.9 |

100 |

Solid carbide internal coolant twist drill, 5xD

★Manufacturing characteristics

1. Dimensions are manufactured in accordance with DIN6537 standard

2. 2. Chisel edge correction IRK standard

3. Main edge angle 140°

4. Specially designed chip groove for easy chip removal

5. Blade diameter tolerance m7

6. Shank diameter type refers to DIN6535HA h6

★Usage Features

Used for processing common materials such as structural steel, alloy steel, stainless steel, etc.; has strong centering ability, can obtain stable dimensional accuracy and good surface quality; suitable for occasions where the processing system has excellent rigidity.

|

Size series |

Size Features |

||

|

D1 |

L1 |

D |

L |

|

3 |

20 |

3 |

50 |

|

3.1-4 |

25 |

4 |

53 |

|

4.1-5 |

28 |

6 |

55 |

|

5.1-6 |

36 |

6 |

75 |

|

6.1-7 |

53 |

8 |

91 |

|

7.1-8 |

53 |

8 |

91 |

|

8.1-9 |

61 |

10 |

103 |

|

9.1-10 |

61 |

10 |

103 |

|

10.1-11 |

71 |

12 |

110 |

|

11.1-12 |

71 |

12 |

110 |

|

12.1-13 |

77 |

14 |

125 |

|

13.1-14 |

77 |

14 |

125 |

|

14.1-15 |

83 |

16 |

133 |

|

15.1-16 |

83 |

16 |

133 |

Note :

1. The handle can be customized according to DIN6535HAHB/HE

2. Customization example D1102-0330 (10 pieces)

Solid carbide step drill

★Manufacturing characteristics

1. Dimensions are manufactured according to DIN6537 standard

2. Chisel edge correction IRK standard

3. Main edge angle 118°

4. Special chip groove design for easy chip removal

5. Blade diameter tolerance m7

6. Shank diameter type refer to DIN6535HA h6

★Usage Features

It is suitable for processing gray cast iron, ductile iron, cast aluminum alloy and other materials. It has strong centering ability, stable cutting form, stable dimensional accuracy and good surface quality; it is suitable for high-speed and high-feed cutting.

|

Size series |

Size Features |

|||

|

dc |

lc |

If |

ds |

lo |

|

3.3 |

11.4 |

28 |

6 |

66 |

|

4.2 |

13.6 |

28 |

6 |

66 |

|

5.0 |

16.5 |

41 |

8 |

79 |

|

6.8 |

21.0 |

47 |

10 |

89 |

|

8.5 |

25.5 |

55 |

12 |

102 |

|

10.2 |

30.0 |

60 |

14 |

107 |

|

12.0 |

34.5 |

65 |

16 |

115 |

|

14.0 |

38.5 |

73 |

18 |

123 |

Note :

1. The handle can be customized according to DIN6535HAHB/HE

2. Customization example D1102-0330 (10 pieces)

INQUIRY

Related product categories

- tungsten carbide roll ring suppliers for mance roller rings

- tungsten carbide roll ring suppliers for section mills

- carbide roll rings for seamless tube mills

- roll rings with high wear resistance for high-temperature applications

- tungsten carbide roll rings for stainless steel production

- bulk purchase of roll rings for high-speed wire rod mills

- how to select carbide roll rings Japan

- cemented carbide roll ring manufacturers Japan

- high grinding tungsten carbide for roughing

- cemented carbide milling insert

- china cnc end mill kit

- carbide milling tools

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de