Superalloy Composite Heating Plate

Product Information

- Product Name: Superalloy Composite Heating Plate

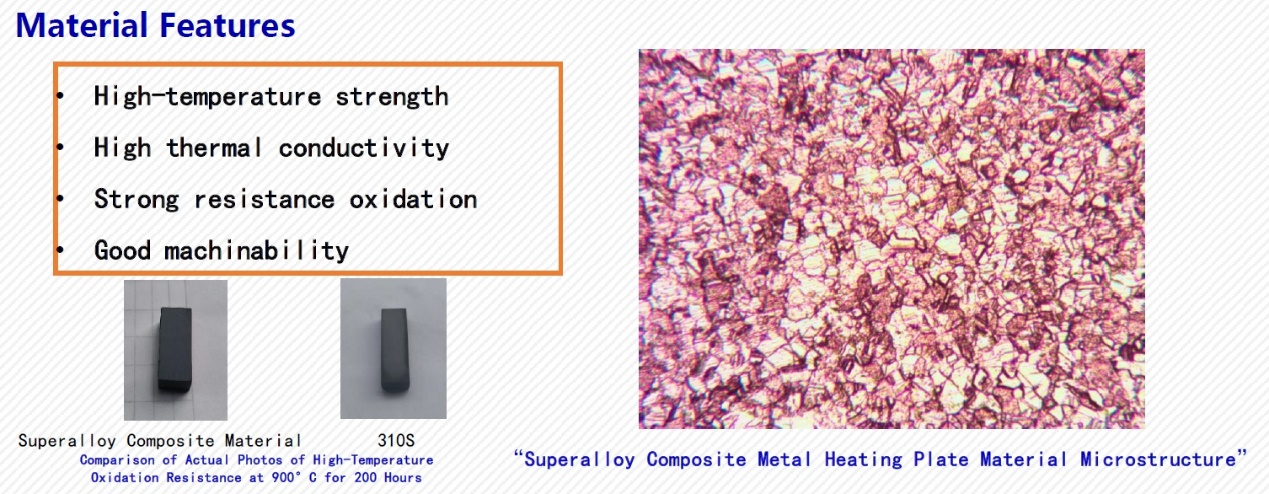

- Material: cermet, tungsten carbide and binder.

- Application apparatus: 3D curved glass hot bending machine 、Precision molding machine for freeform surfaces (HUD)

- Machinable workpiece: 3D curved glass, Automotive HUD screens, LiDAR windows, Camera lens

- Advantage:

1)Excellent tempering resistance.

2)High thermal conductivity (40-44 W/(m·K)).

3)Low coefficient of thermal expansion (10 × 10⁻⁶/°C).

4)Softened after heat treatment (below 45 HRC).

- Brief Introduction

The heating plate (or heater plate) is a crucial component of the 3D glass bending machine, functioning as the primary heat source for the entire bending system. Heating tubes are embedded in the plate to generate heat, which is then evenly distributed across the heat distribution plate. This heat is ultimately transferred to the glass, causing it to soften and become moldable within the mold.

Description

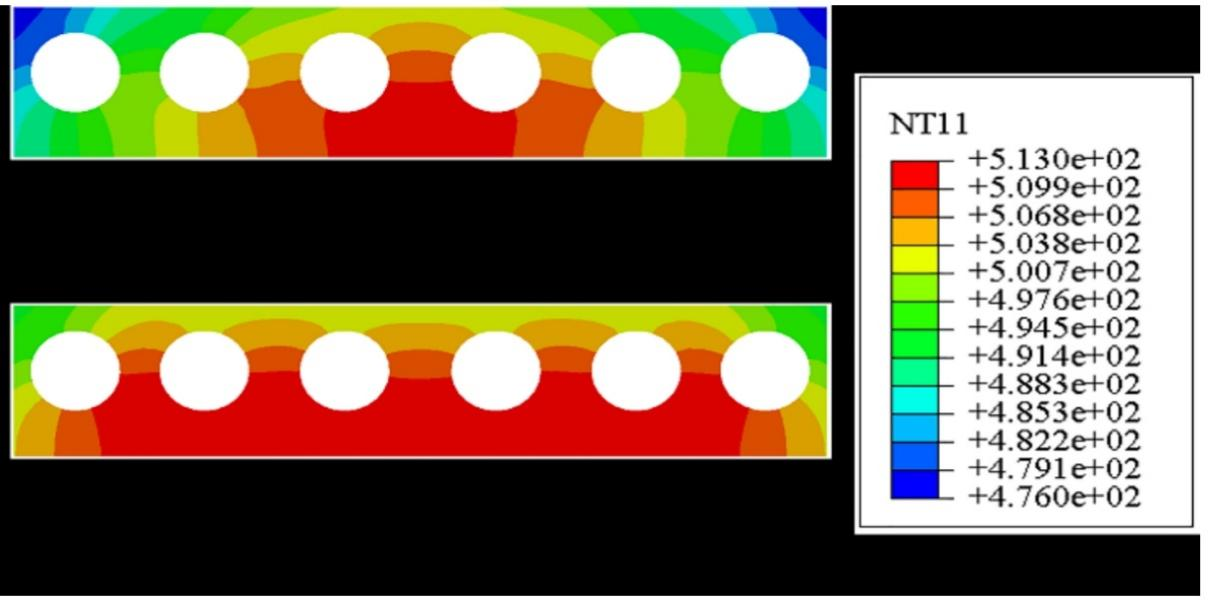

Based on the simulation results, the temperature distribution within the heating plate

INQUIRY

Related product categories

- thermally stable carbide rolls for mance rolls

- roll rings for hot rolling

- tungsten carbide rolls Vietnam for roughing stands

- tungsten carbide roll rings

- Chinese manufacturer of roll rings for reversing mills

- supplier of roll rings for roughing stands

- cemented carbide roll ring manufacturers Iraq

- top suppliers of tungsten carbide roll rings Ukraine

- cemented carbide bush for sign making

- china milling machine bits

- china end mill bits

- china 1 mm cnc end mill

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de