Technical Parameter

Cemented carbide roll rings (also known as Tungsten Carbide Roll Rings) offer excellent thermal conductivity and outperform first-generation cast-iron and high-speed-steel rolls in heat resistance, wear resistance, and strength, with minimal hardness reduction at high temperatures. Developed alongside high-speed wire rod mills, they are now extensively applied in the finishing stands for manufacturing high-speed wire, rebar, and deformed steel bars.

| Roughness of carbide rolls | |

| Inner hole roughness: | 0.4μm |

| Periphery roughness: | 0.4μm |

| End face roughness: | 0.4μm |

| The specification of the cemented carbide roller | ||

| Range of O.D. | Range of I.D. | Range of Height |

| 145-330 | 87-260 | 45-130 |

| The allowable deviation of carbide roll rings | |||

| Radial runout of groove: | ≤0.013mm | Radial runout of excircle: | ≤0.013mm |

| End face runout: | ≤0.02mm | End face planeness: | ≤0.01mm |

| End face parallelism: ≤0.01mm | ≤0.01mm | Inner hole cylindericity: | ≤0.01m |

| The tolerances allowable for the outer diameter, inner diameter, and height of roll rings. | |||||

| Precision Index | 1 | 2 | 3 | 4 | Customization Service We can customize your size & materials according to the drawings provided by customers. |

| O.D. (±) | 0.02 | 0.05 | 0.1 | 0.15 | |

| I.D. (±) | IT 5 | IT6 | IT7 | IT8 | |

| Height(-) | 0.03 | 0.1 | 0.2 | 0.5 | |

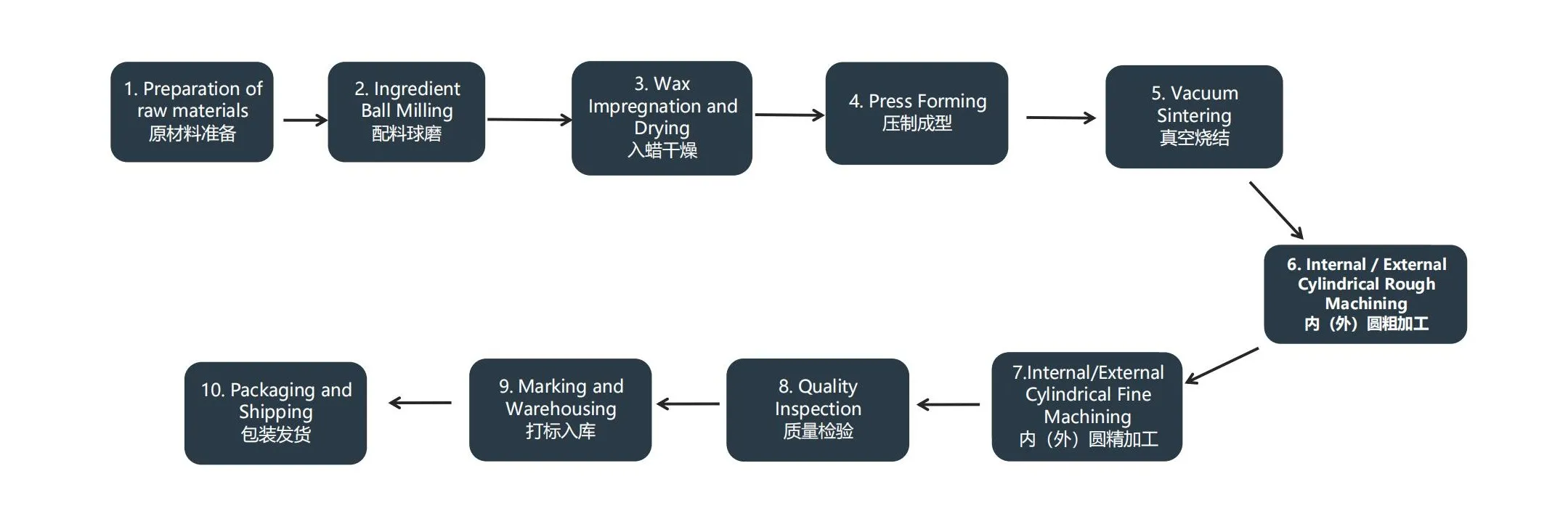

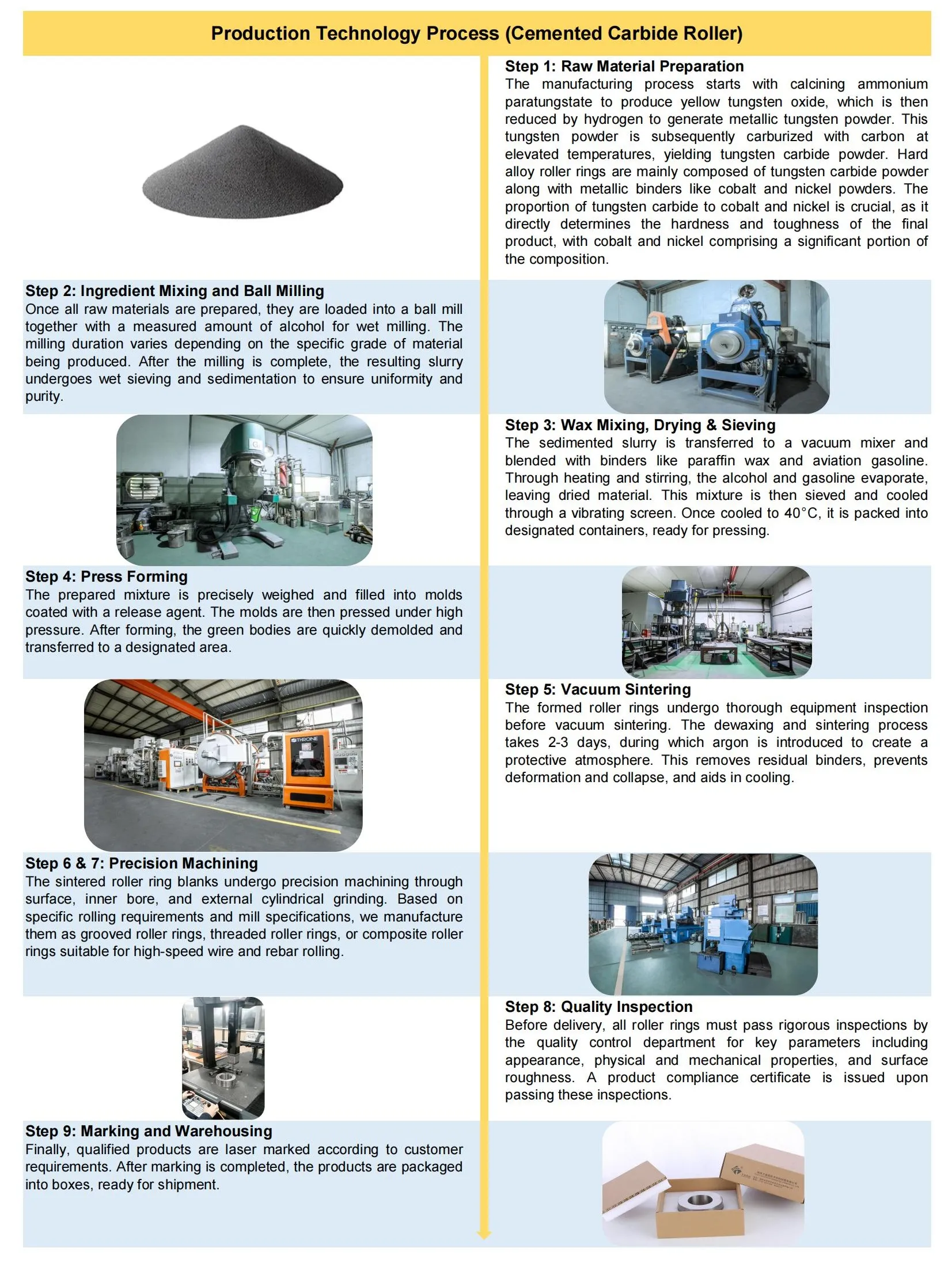

Production Technology Process

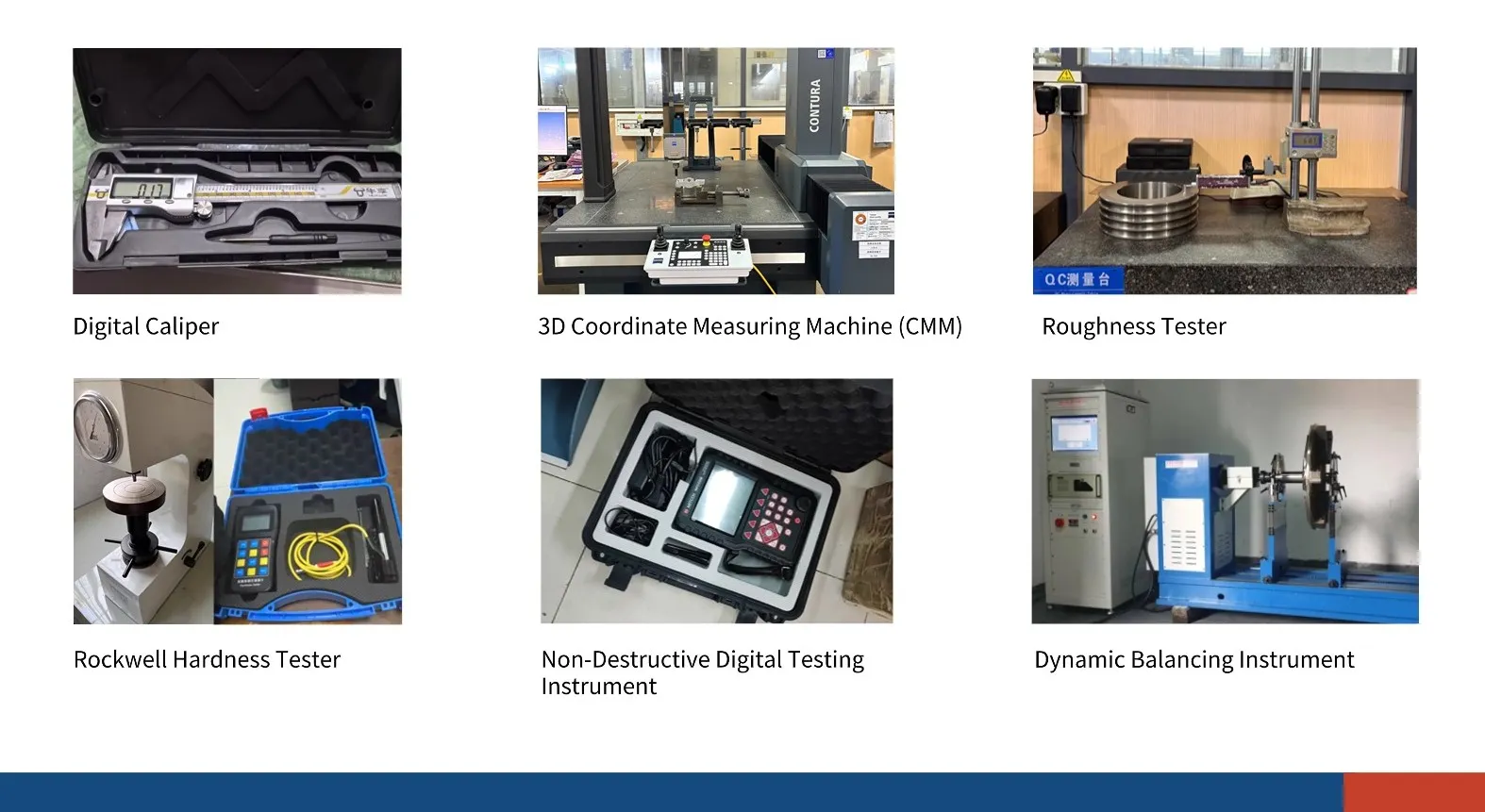

Quality Inspection Equipment

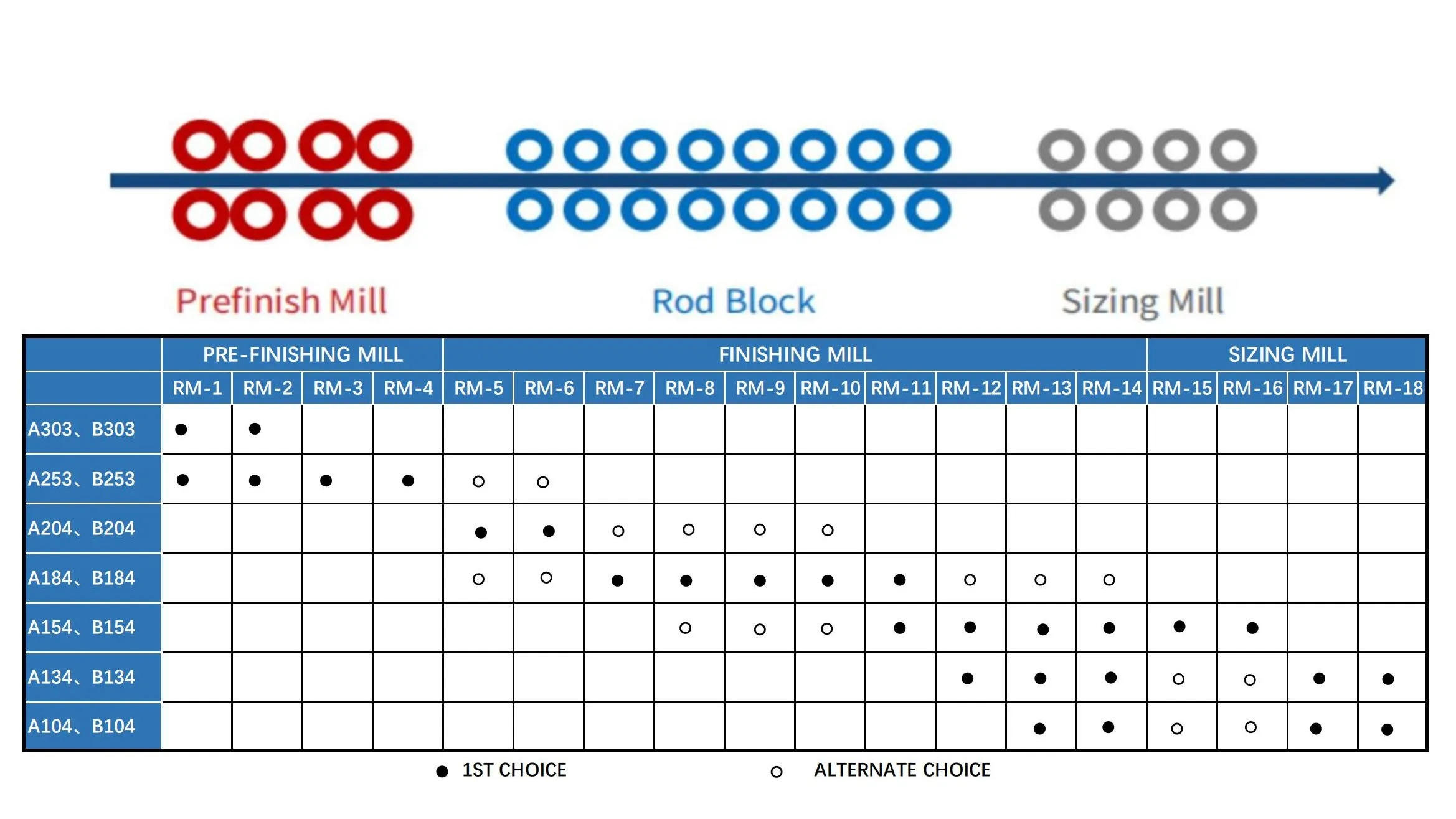

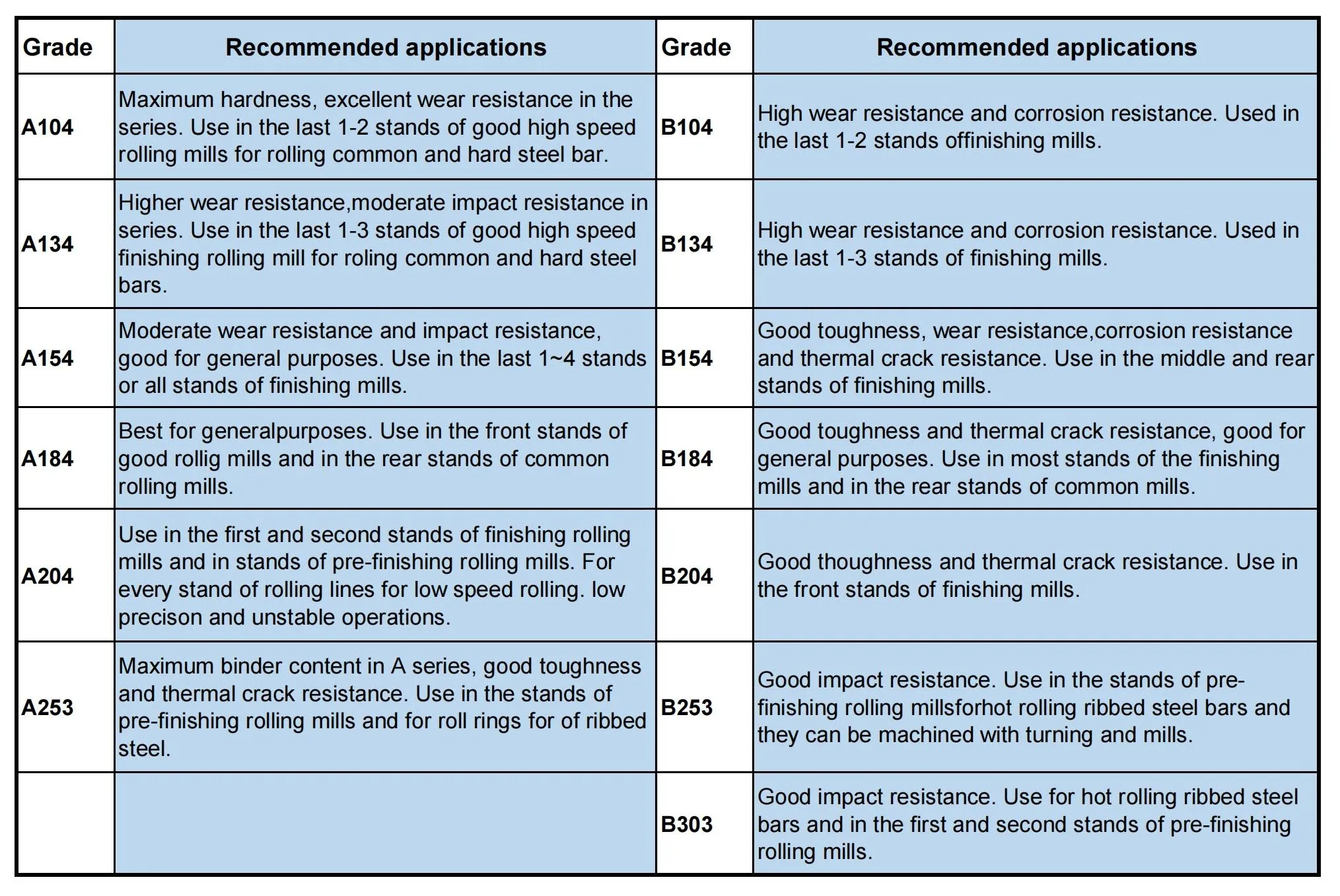

Applications in Steel Rolling Mill Operations

Tungsten carbide roll rings are widely used across roughing, intermediate, and finishing stands in steel rolling mill production lines. Their high wear resistance, thermal stability, and precision groove performance make them essential for shaping rebar, wire rod, and other profiles. In a rolling mill in steel plant, these rings help maintain consistent rolling accuracy, reduce downtimes, and extend overall service life under heavy-load and continuous-operation conditions.

View more carbide roller rings for steel rolling mill applications

EN

EN UR

UR ru

ru bn

bn ar

ar ky

ky th

th fil

fil vi

vi ms

ms tr

tr ro

ro pt

pt es

es af

af fa

fa uk

uk nl

nl pl

pl fr

fr de

de